Ever thought to yourself – how do wind turbines work?

With the 2021 United Nations Climate Change Conference (COP26) having ended just a few days ago, renewable energy has yet again become a hot topic.

One such method of generating renewable energy is through the use of wind turbines.

This method is one of the most studied and technologically advanced ways of harnessing green energy for the following reasons:

- Wind being readily available.

- Their installation capacity (743 GW worldwide according to the 2021 Global Wind Report).

- Their cost reduction trend.

- How much money manufacturers are investing in research and development – bigger and better machines are coming out almost every year.

Some of you may confuse these machines for simple ventilation fans used to care for livestock. However, the technology and working principles driving these wind turbines are much more complex.

In this article, we’ll sum up the workings of a wind turbine and its main components for you.

Table of Contents

How Does a Wind Turbine Work?

Using wind turbines for electricity generation is relatively new – the industry has been around since the 80s and 90s). However, these machines have been performing tasks for humans for much, much longer.

Let’s go back, way back, to the Middle Ages. If you needed to grind some grains or drain water from an area, a windmill would do the job for you. While the size and overall look may seem different, they were basically simple wind turbines, functioning under the same principles.

“Okay, I have an idea of what they’re capable of, but how do they actually work?”

Understanding the energy conversion process that takes in a wind turbine will help you to answer this question.

Wind Turbine Energy Conversion Process

Step 1

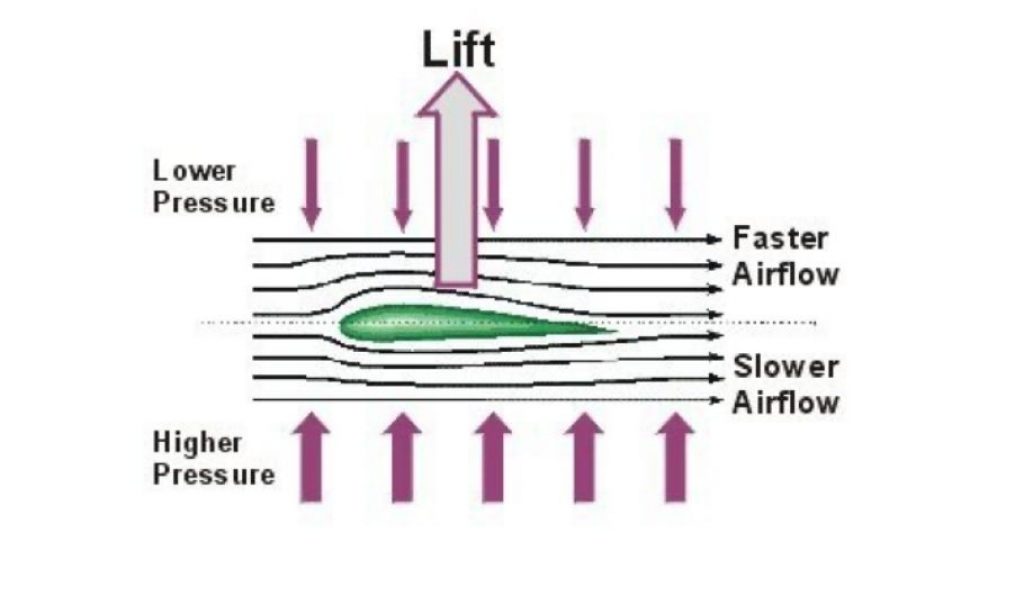

Wind, which is basically an air current flowing around a certain area, carries an amount of kinetic energy. When wind flows through a wind blade, it breaks into two, now flowing above and below the wind blade.

The aerodynamic design of the blade causes the wind to blow at different speeds on each side of the blade. This generates a pressure difference, creating “lift and drag” forces. In this way, the kinetic energy of the wind is now effectively lifting the wind blade.

An airplane is a great real-world example of this process.

Step 2

The lift forces applied to the wind blade (with respect to the wind blade axis) generate torque and rotational movement. At this point, the wind’s kinetic energy transforms into rotational energy.

Step 3

This rotating axis connects to a generator which transforms rotational energy into electric energy, via the electromechanical conversion principle.

Finally, the wind’s kinetic energy is converted into electrical energy.

Step 4

Sure, we now have electrical energy but it’s not yet “compatible” with the electric energy we use in the grid. Now what?

Wind turbines come with “converters”. These converters help match the voltage and frequency characteristics of the generated energy with those of the electric grid. Now our energy is ready to be transmitted and distributed for use.

What Are The Main Components Of A Wind Turbine?

Wind turbines are made up of many different components. These all work together to ensure that the energy conversion process takes place smoothly and efficiently.

On that note, let’s take a closer look at the components that make all of this possible.

For this analysis, we’ll look at the most widespread and advanced type of wind turbine – the Horizontal Axis Wind Turbine (HAWT). These are used worldwide for both onshore and offshore applications.

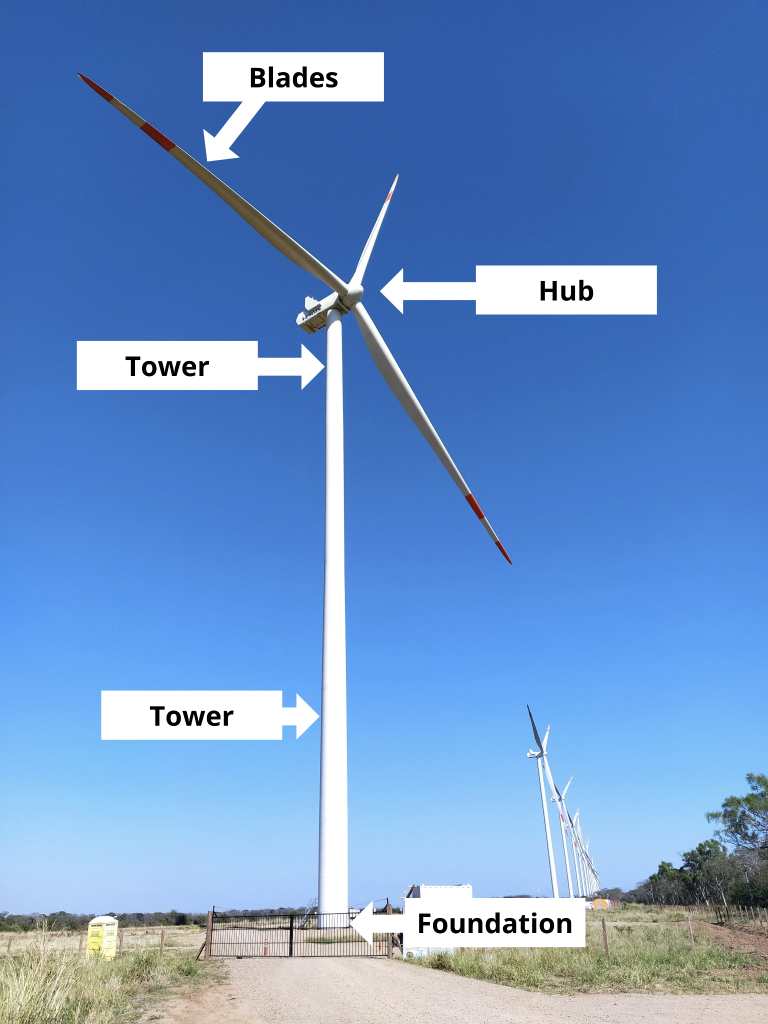

Starting from the ground up, the main components are as follows:

Foundation

A hidden – it’s usually buried or underwater – but a key component of a wind turbine. It’s also the most important and critical function of wind farm construction.

Its main purpose is to transfer all the generated loads on top of the wind turbine to the ground.

As you’ll recall from earlier on, during wind energy conversion, drag forces occur on the wind blades. This generates an overturning moment with regard to the wind turbine’s base.

As such, the foundation has to be robust enough to withstand these loads throughout the turbine’s lifespan – generally 20 years.

In general terms, onshore wind turbines use spread or pile foundations. This mostly depends on soil properties and the local geology of the construction area.

On the other hand, offshore wind turbines have a wider variety of foundations, such as gravity, monopile, multipod, or floating substructures. The use of each will depend on the turbine size and water depth.

Tower

The tower’s main purpose is to give as much height as possible to the wind blades (wind resource is better at higher altitudes)while being robust enough to withstand the weight of the equipment on top of the wind turbine. Additionally, it helps assist with the transmission of all the generated loads from above to the foundation.

Smaller wind turbines generally used lattice towers But as the wind industry kept on evolving, manufacturers had to innovate and find different materials and construction methods to produce towers.

Nowadays, most towers are being built out of concrete, rolled steel, or even wood. In addition to this, they generally come separated into sections, are built in a factory, and shipped to construction sites for on-site assembly.

Nacelle

Up next, we have the nacelle. This houses all the equipment that makes the functioning of a wind turbine possible. A typical nacelle holds the following equipment:

- Gearbox – Used to increase the slow rotation speed of the shaft of a wind turbine (around 12-15 RPM) to a shaft rotating at a higher speed (around 600 RPM). This makes it suitable for connection to an electric generator. Not all manufacturers and technologies use this component.

- Generator – Responsible for converting rotational energy to electrical energy. Typically an alternating current (AC), asynchronous generator.

- Converter – As explained earlier, this component is in charge of making eletrical energy that has been generated compatible with the electrical grid. It uses power electronic technology such as thyristors for this purpose. Some manufacturers place this component on the base, inside the tower of the wind turbine.

- Transformer – Responsible for increasing the low-voltage output of the converter to a high-voltage value, in order to reduce electrical losses. Some manufacturers place this equipment on the base of the wind turbine.

- Hydraulic, pneumatic or electric control equipment – Used to control the pitch of the wind blades, and the yaw of the nacelle. This helps position the wind turbine in an optimal position according to wind direction.

Hub

Also known as the “nose” of the wind turbine, its main purpose is to mechanically connect the three blades of the wind turbine to the slow rotating axis of the wind turbine.

It also holds the hydraulic, pneumatic, or electric control actuators used for the pitch of the blades.

Pitch control is a key component of a wind turbine, as it allows a wind blade to be at an optimal angle depending on the wind speed. Additionally, it helps to stop a blade by positioning it in a feather position when wind conditions are high and dangerous for the turbine.

Blades

Last, but not least, we have the blades of the turbine. These are made of a single piece of composite material that generally uses fiberglass or carbon-fiber polymers.

Blade construction and design is a very complex process, as they have to be as big as possible to cover a wide area.

In addition to this, they must use lightweight but resistant materials in order to harness as much energy as possible from the wind and to withstand the fluctuating forces coming from the wind.

Final Thoughts

Wind turbines are fascinating pieces of equipment that allow us to harness energy from a widely available renewable source.

As it’s still a relatively new field, each manufacturer has different ways of designing their wind turbines. Many of them are also still testing out different technologies.

Ultimately, only time will tell which designs will prevail for the further development of this industry.