Running power tools with an inverter is doable if you have the correct size component.

Inverters come in many sizes, from a few hundred watts (W) to several kilowatts (kW). A large inverter will run power tools suitable for quick fixes or DIY projects. However, only some people need a +5kW inverter; this is where this article comes into play — to help you select the correct inverter size to run your power tools.

Here, we will discuss the minimum inverter size needed to run the following power tools:

- Drill

- Circular Saw

- Sander

- Grinder

- Jack Hammer

Additionally, we relate a real-world experience of building a house with a 3.5kW inverter and a complete set of wired power tools.

Table of Contents

Can An Inverter Run Power Tools?

Yes, an inverter is capable of running power tools. However, its size dictates the type and number of tools it can power.

Inverters are becoming increasingly popular, like solar panels and portable power stations. Plugged into a battery, they convert DC into high-quality AC electricity similar to the standards of a utility company (120V, 60Hz).

This is incredibly convenient as it allows you to power your tools anywhere, whether on a boat, in your RV, during a camping trip, or simply where there is no access to grid electricity.

Most people would assume a 1000W inverter is enough to run a 1000W drill, but they’d be mistaken, and we’re going to demonstrate why this is the case.

Type Of Electrical Loads

There are two primary types of electrical loads:

- Resistive

- Inductive

Resistive loads

Resistive loads are the simplest type; they involve a resistance that converts electricity into heat. Among resistive loads, you’ll find:

- Electric ovens

- Electric heaters

- Toasters

- Incandescent lights

These loads have an efficiency close to 1. This means a 1000W electric heater truly uses 1000W from an inverter.

Inductive loads

Inductive loads involve a motor that converts AC electricity into magnetic energy and, ultimately, mechanical energy. Here are a few examples of inductive loads:

- Refrigerator

- Washing machine

- Water pump

- Microwave oven

- Air conditioning unit

- Any electric motor

You can expect an efficiency between 50%-90% with inductive loads, depending on the appliances. This means that a 1000W water pump requires 1300W (efficiency 70%) to function correctly.

Why Inductive Loads Are Not Efficient: Power Factor

When an electric motor connects to a power source, it creates an electromotive force. This voltage moves in opposition to the voltage from your energy source.

Due to this property, inductive loads such as power tools are not 100% efficient, and you’ll likely experience a power surge when turning your power tools on and off.

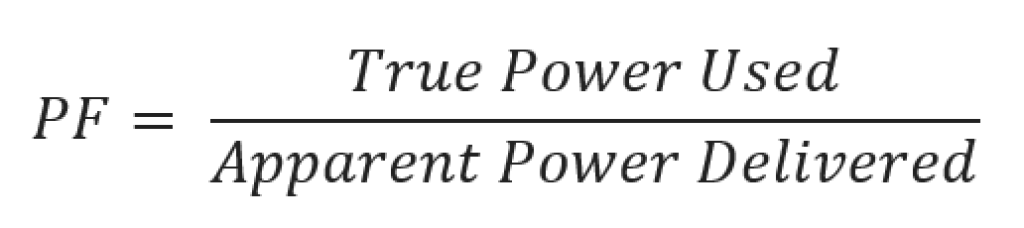

Enter the power factor (PF), introduced to express the efficiency of an inductive load. The power factor is calculated by dividing the working power, in kilowatts (kW), by the apparent power, in kilovolt amperes (kVA), also called demand.

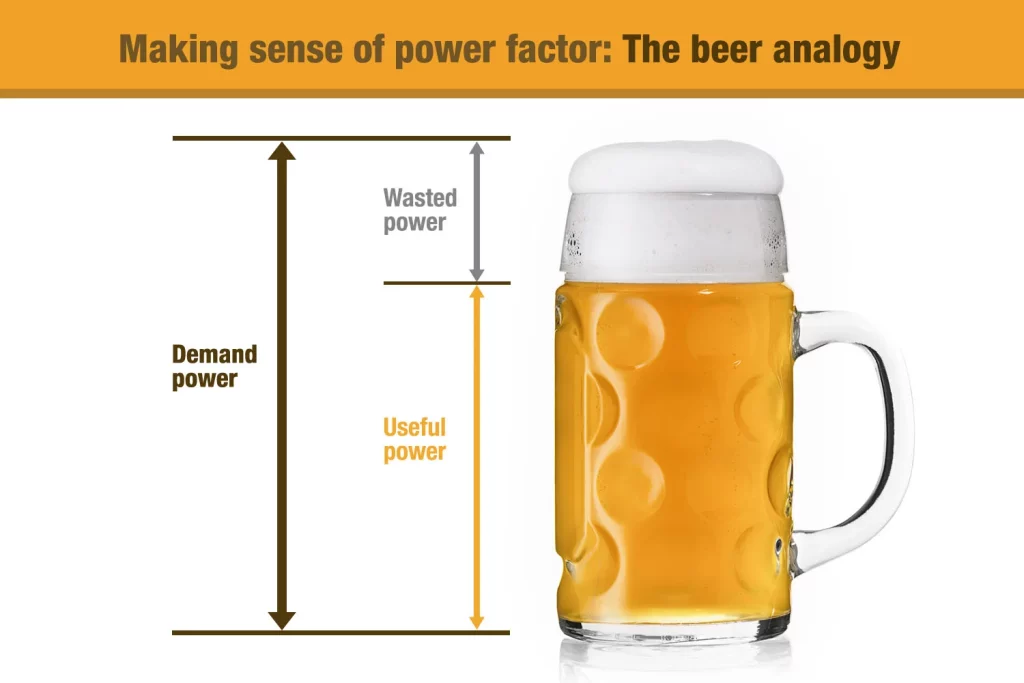

You must multiply the voltage (V) by the current intensity (A) while your power tool is running to obtain the apparent power value. The beer analogy is a great way to understand the concept of the power factor:

Source: fluke.com

- The beer represents the active power that the power tool uses

- The foam represents the reactive power — wasted power during the tool operation.

- The entire mug represents the demand power (apparent power) that the inverter supplies

In the end, this is the apparent power (kVA) that your inverter must be able to supply.

Scenario

Let’s say you’re about to use a 1000W power tool. On average, the power factor for this type of equipment is 0.8. Consequently, to run a 1000W power tool, you’ll need a 1200W inverter.

In addition, your inverter must be able to handle a power surge when the tool starts. The power surge only lasts 1 to 3 seconds at max and can be as high as 2 times the rated power of your power tool.

What Size Inverter Is Needed To Run A Drill?

To run a drill, you’ll need an inverter between 650W and 1800W, depending on the tool’s power. Let’s see how we arrived at these figures:

As illustrated in the chart below, the power of a corded drill varies between 540W and 1500W.

With a power factor of 0.8, you’ll need to oversize your inverter by 20%. Consequently, you’ll have to get an inverter between 650W and 1800W with a power surge capacity between 1,080W and 3,120W (2 seconds).

| Drill | Illustration | Drill-Rated Power (W) | Min. Inverter SIze (W) | Inverter Surge Power (2s) |

|---|---|---|---|---|

| Black+Decker Hammer drill |  | 780 | 936 | 1,560 |

| GalaxPro Hammer Drill |  | 540 | 648 | 1,080 |

| Dewalt corded drill |  | 960 | 1,152 | 1,920 |

| Dewinner Hammer Drill |  | 1,560 | 1,872 | 3,120 |

What Size Inverter Is Needed To Run A Circular Saw?

To run a 1800W circular saw, you’ll need a 2,200W inverter. Let’s see how we arrived at this figure:

Circular saws are among the most powerful domestic power tools reaching up to 1,800W. Their power factor is around 0.8. As such, you’ll need to oversize the inverter by 20%.

For a 1,800W circular saw, you’ll need an inverter with a minimum power output of 2,160W and a power surge capacity of 3,600W.

| Circular Saw | Illustration | Rated Power (W) | Min. Inverter Size (W) | Inverter Surge Power (2s) |

|---|---|---|---|---|

| Makita 5007MG circular saw |  | 1,800 | 2,160 | 3,600 |

| Skil circular saw |  | 1,800 | 2,160 | 3,600 |

| BOSCH CS10 |  | 1,800 | 2,160 | 3,600 |

| DEWALT 7-1/4-Inch Circular Saw |  | 1,800 | 2,160 | 3,600 |

What Size Inverter Is Needed To Run Sanders & Grinders?

To run sanders and grinders, you’ll need an inverter between 250W and 2,200W, depending on your equipment’s power. Let’s see how we arrived at these figures:

The power of a corded sander varies between 200W and 360W. With a power factor of 0.8, you’ll have to oversize your inverter by 20%. Consequently, you’ll need an inverter between 250W and 450W with a power surge capacity between 720W and 400W (2 seconds).

Grinders are slightly more powerful than sanders, ranging from 720W to 1,800W. They have the same power factor of 0.8. Consequently, your grinder will need an inverter between 870W and 2,200W with a power surge capacity between 1,440W and 3,600W (2 seconds).

| Sander & Grinder | Illustration | Rated Power (W) | Min. Inverter Size (W) | Inverter Surge Power (2s) |

|---|---|---|---|---|

| DEWALT Random Orbit Sander |  | 360 | 432 | 720 |

| Makita Sheet Finishing Sander |  | 204 | 245 | 408 |

| Makita GA9040S 9″ Angle Grinder |  | 1,800 | 2,160 | 3,600 |

| BOSCH 1375A Corded Angle Grinder |  | 720 | 864 | 1,440 |

What Size Inverter Is Needed To Run A Jack Hammer?

To run a jackhammer, you’ll need an inverter with a minimum power of 2,200W. Let’s see how we arrived at this figure:

Demolition hammers are extremely powerful and require up to 1,800W to operate. Their power factor is around 0.8. Consequently, you’ll need to oversize the inverter by 20%. For a 1,800W jackhammer, you’ll need an inverter with a minimum power output of 2,160W and a power surge capacity of 3,600W (2s).

| Jackhammer | Illustration | Rated power (W) | Min. Inverter size (W) | Inverter surge power (2s) |

|---|---|---|---|---|

| Berserker 1700W 30-Pound SDS-Hex Jack Hammer |  | 1,700 | 2,040 | 3,400 |

| BOSCH BH2760VC BRUTE Breaker Hammer |  | 1,800 | 2,160 | 3,600 |

| Makita HM1307CB 35 lb. Demolition Hammer |  | 1,680 | 2,016 | 3,360 |

Why Do Inverters Need To Be Big To Run Power Tools?

There are two reasons why you need a big inverter to run power tools:

- Power tools draw a lot of power (from 250W to 2,000W).

- The nature of their electrical load. Power tools, refrigerators, and aircon units are inductive loads, which means they are not 100% efficient.

Usually, a power tool is 80% efficient (power factor=0.8), which means that running a 1,000W power tool demands at least a 1,200W inverter.

Moreover, inductive loads are prone to power surge upon starting, which could be as high as 2 times their rated power.

Real-Life Experience: What Power Tool Will A 3500W Off-Grid Inverter Run?

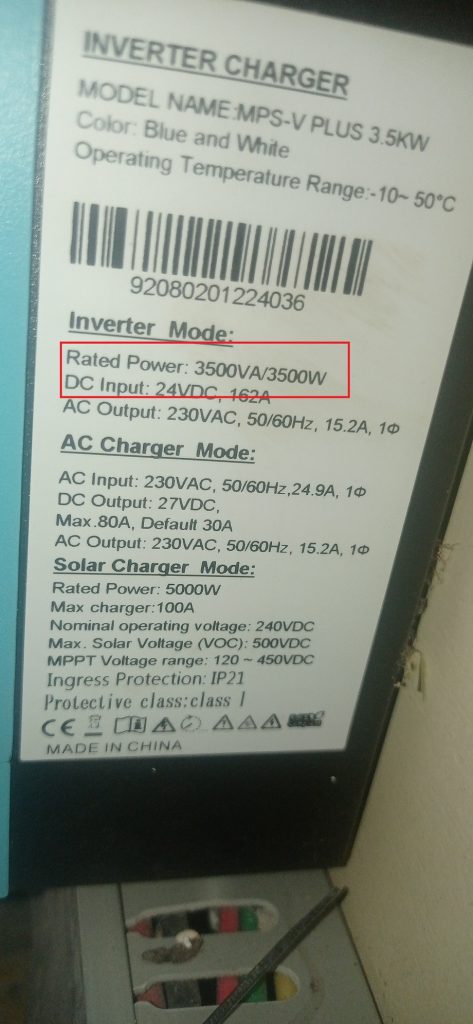

For over a year, my team and I have been building multiple small houses and compounds on private property using a 3,500W inverter connected to a 5kW solar array and a 10 kWh battery bank.

Here are the power tools we’ve been using:

- drill

- grinder

- sander

- sprayer

- circular saw

- table saw

- planner

- portable welding machine

- demolition hammer

The power of our tools varies from 350W for the sander up to 1,500W for the table saw. Our experience showed that a 3,500W inverter (7,000W surge) had no problem running individual tools.

Slightly more challenging, though, is running multiple power tools simultaneously. In this scenario, it’s crucial to identify the most powerful tools, such as the circular and table saw, the demolition hammer, and the portable welding machine.

We discovered that we could run all the smaller power tools (drills, grinder, sander, sprayer, planner) simultaneously without overloading the inverter.

When it came to more powerful tools, we could run one large tool with two smaller ones.

We also measured the PF of our tools, and it was close to 0.8 (80% efficiency).

In conclusion, a 3.5kW inverter can effectively run power tools and satisfy the needs of the most demanding projects.

Final Thoughts

An inverter is a convenient way to supply AC electricity from a battery and power equipment in an off-grid situation.

We demonstrated that power tools are inductive loads prone to power surges and require around 20 to 25% extra power vs. their rated power to function correctly.

Additionally, we discovered that a 2,500W inverter has no problem running the most demanding power tools, such as a demolition hammer or a circular saw.

Based on our experience, for a larger project with multiple power tools, we recommend a 3500W inverter as a minimum requirement.

Final tip: Preserve your inverter: Don’t overload, always keep a 20% safety margin from the maximum continuous power capacity.