With the construction industry moving towards a zero-carbon future, recycled building materials are becoming more and more popular.

Researchers and scientists constantly develop new materials and building methods using recycled and green material.

In the architectural field, we say that a house has a lifespan of 50 years. After that, the house requires renovation and maintenance. When buying a home, the new owner often has some alterations in mind. For example, a new owner would knock down walls, install new windows and build new rooms.

But what happens to all the building rubble? And how can you up-cycle it and reuse it in your next build?

Table of Contents

What Is Recycled Building Material?

Any material that comes from a building site for reuse can be considered recycled building material.

Builders and contractors can recycle various materials on a construction site. For example, builders can crush bricks down into aggregate for concrete, make use of reclaimed timber, and even reuse plastics or rubber.

The best thing about recycled materials is that you can get very creative when using them, and any architect worth their salt will embrace the opportunity to flex their creative muscle.

10 Examples of Recycled Building Material

Below are ten examples of recycled building material used in construction today.

1. Clay Bricks

Source: recycledbrickcentre

Clay bricks have been around since 7000 BCE, so they’re not a new building material.

They have a lifespan of 500 years. This long lifespan means that you could technically reuse them for multiple building projects.

In addition to builders being able to reuse these bricks for projects such as new walls, they can also crush them down into chips and use them as aggregate in concrete or gravel replacement.

But it doesn’t just stop there. They can also refine them into dust and use them as fill-sand, or make them into new bricks.

2. Plant-Based Polyurethane Foam Boards

Source: generalplastics

Polyurethane is a type of plastic that you can use as an insulator in your home. What’s more, manufacturers can make plant-based plastic better for the environment by using oils from plants. For example, oil from bamboo, hemp, and kelp effectively create a sustainable insulation board.

Benefits of plant-based polyurethane boards include good heat transfer resistance and quality sound insulation. Additionally, plant-based polyurethane is mould and insect resistant.

To find out more about insulation and why it’s essential for your home, you can read our article on home insulation.

3. Hempcrete

Source: Westword

Hempcrete is a sustainable alternative to concrete. The material consists of natural hemp fibres and is bound with lime to create a concrete-like material.

While cement production contributes to 8% of global CO2 emission, hempcrete is carbon negative. Carbon negative means that hempcrete removes carbon dioxide from the atmosphere rather than emitting it.

Not only is it sustainable, but it’s also self-insulating to the point that it meets most regulations without additional insulation.

The only downfall – it isn’t a load-bearing material. As a result, hempcrete won’t be able to support your home’s roof structure without a frame made from steel or timber.

4. Ecobricks

Source: ecobricks.org

Ecobricks is a global initiative that directly tackles plastic waste pollution. An Ecobrick is a plastic bottle that you fill with small plastic waste which creates a firm and solid plastic brick. You can then use these ‘plastic bricks’ to build structures like vegetable gardens are even walls.

Plastic can take up to 450 years to decompose, almost as long as a clay brick can last. As a result, Ecobricks are an affordable substitute for regular bricks.

5. Bamboo

Source: yankodesign

The use of bamboo in construction is nothing new. However, with recent studies revealing undiscovered properties, bamboo has become one of the most sustainable building materials.

Whilst it’s not technically timber and a type of grass, bamboo has impressive strength and flexibility. It’s three times stronger than timber beams and more robust than concrete when it comes to compression. In terms of its tensile strength (the ability to resist tension), bamboo is stronger than steel.

Bamboo is recyclable after its initial use. For example, manufacturers can strip down the bamboo used in construction to its fibres.

Common bamboo products include bamboo cutlery, bamboo sheets and bamboo flooring which consists of bamboo fibres.

6. Rubber Tyres

Source: lostecnicos

Tyres make for fantastic recycled building materials. They consist of natural and synthetic rubber. Rubber is a broad term that describes a variety of compounds – each compound has its unique properties.

Tyres that aren’t roadworthy are disposed of and often end up in waste yards. This is not ideal as there are many innovative ways to include tyres in your home.

Here are some examples:

- You can compact the typres with earth to create a retaining wall.

- You can shred them into small pieces and use them as paving.

- Tyres are great for creating DIY vegetable gardens.

- Tyre swings anyone?

7. Rammed Earth

Source: Archdaily

Rammed earth is a construction method that is taking the world by storm. It has significant advantages when used in your home, allowing for better thermal comfort and insulation.

These walls often consist of soil dug up from the construction site and compacted into a wall. Then, it’s mixed with cement to become firm and stiff.

However, rammed earth has another trick up its sleeve that you can make use of – you can break down the wall and repurpose it. For example, if you crush rammed earth, you can use it as fill sand, compact it again or put it in concrete.

8. Newspaper Wood

Source: Inhabitat

Newspaper wood takes paper and turns it back into wood.

This wood consists of sheets of paper that have been glued together and subjected to immense pressure which compresses the sheets of paper into a solid mass that can be carved and cut into. This concept of compression isn’t new to the construction industry – plywood is made similarly.

Newspaper wood is still a relatively new material. As such, it isn’t used in the actual construction of a house. However, as researchers explore and develop its properties, it’s being used as flooring or a ‘timber’ finishes in your home.

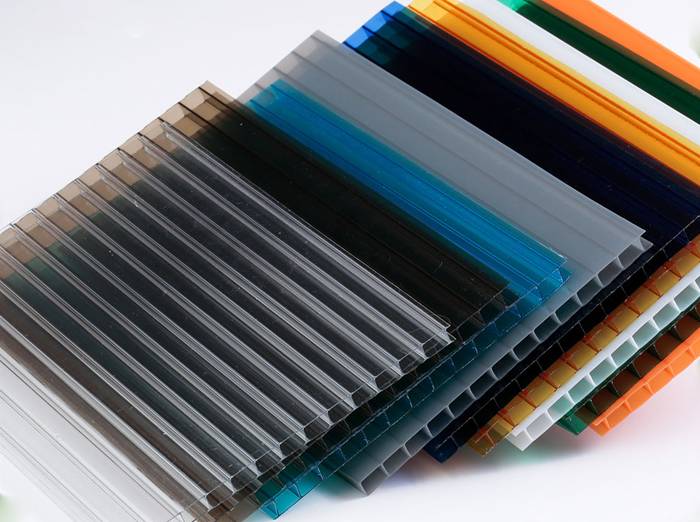

9. Polycarbonate Sheeting

Source: polycarbonatesheetpanel.com

Polycarbonate sheeting is a current building material used for roofs or wall panels. The sheeting is made up of thermoplastic polymers and is 100% recyclable.

Plastic doesn’t exactly have the best reputation from a sustainability point of view. In saying that, it’s possible to melt down these translucent panels and use them repeatedly.

They can create a beautiful and stunning facade that allows light in while still providing privacy.

Ultimately, we can see polycarbonate sheeting developing into more of a sustainable material with multiple benefits.

Source: Archdaily

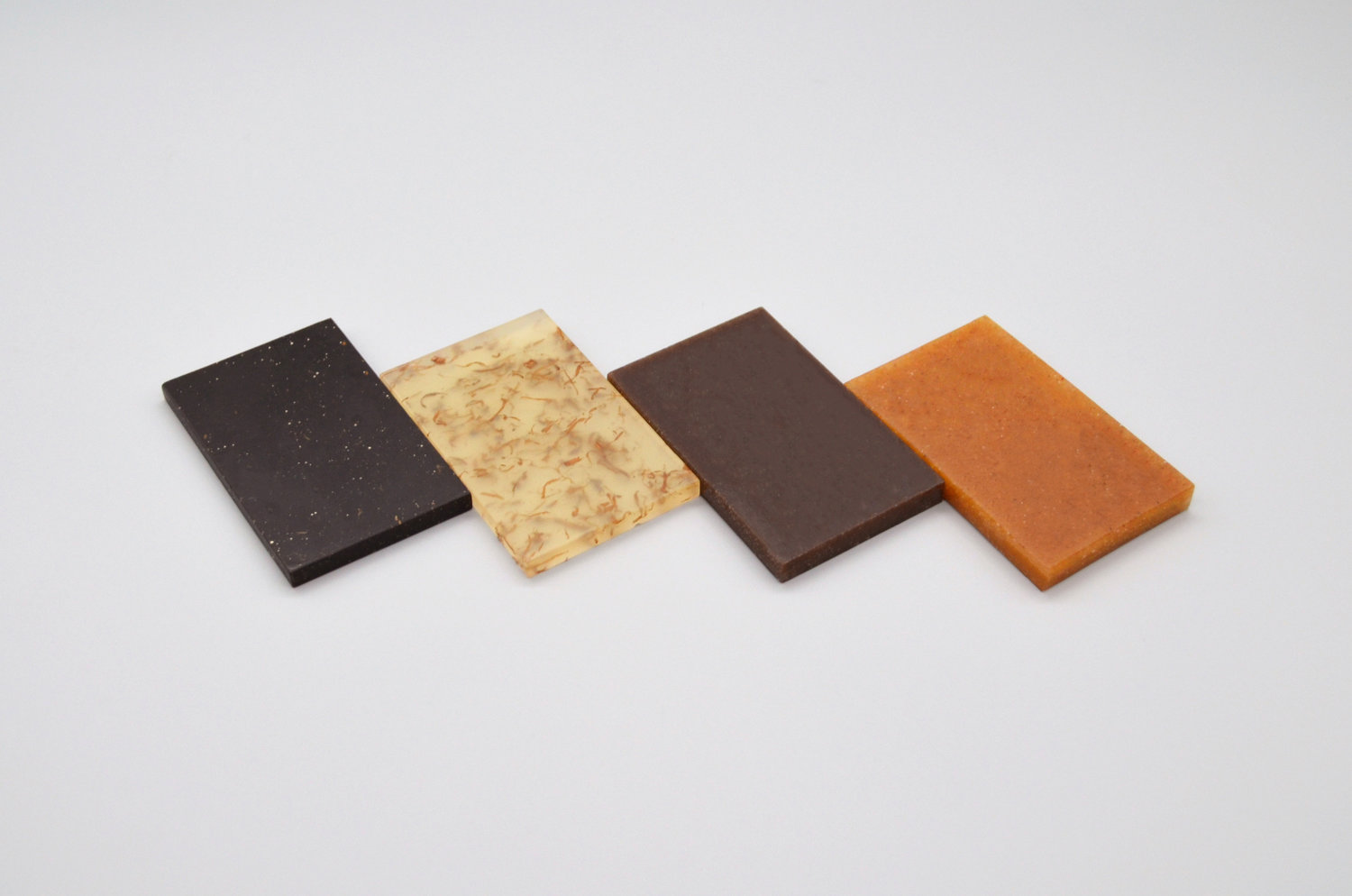

10. Chip[s] Board

Source: Parblex™

This material is a perfect example of exploring different techniques and innovatively replacing single-use materials. Chip[s] board, not to be confused with chipboard, was created by Rowan Minkley and Robert Nicoll.

They invented their product to replace shipboard and similar single-use products with a sustainable alternative. Chip[s] board consists of plastic made from potato waste. This plastic is biodegradable and has a more sustainable production process than other plastics.

This bioplastic merges with potato peels, recycled wood, bamboo and other organic by-products to create a beautiful board.

You can use it for furniture, hand railings and other architectural elements. All you have to do is get creative!

How Are Recycled Materials Used in Buildings?

Using recycled materials in buildings is the fun part! Depending on the material and its properties, architects and contractors can get as creative as they’d like.

Builders can use recycled materials in place of concrete or use them as walling. In addition to this, you can use them for more decorative purposes – think furniture or facades.

You can group most recycled materials into two categories:

- Materials that have already been recycled.

- Materials that you can still recycle.

There are also materials like tyres and clay bricks that you can use and reuse multiple times.

We do however need to keep in mind that all materials age. As such, these materials need to satisfy both the needs of their current owners as well as their future ones.

Is It Cheaper To Build With Recycled Material?

Yes and no.

It depends on the type of material you’re building with. A material like bamboo flooring is a cheaper alternative. However, other recycled products can be more expensive due to their recycling process.

However, there are ways to get around this. You can source most of your recycled building materials from local construction sites or waste yards.

You could ask local building sites if they’re throwing away any demolished bricks when it comes to bricks. Additionally, many brick factories have rejected piles that go for half the price of a new brick.

Tyres that don’t pass quality checks often find themselves in waste yards. If you go to your local waste yard, you could ask them to keep the tyres aside for you. Soon you’ll have enough for your building project for little to nothing.

Ecobricks are essentially free as they consist of plastic waste typically thrown away. On the other hand, Newspaper wood has a more intensive production process and can be more expensive than other alternatives.

What Are The benefits Of Building With Recycled Materials?

Not only do many of the materials come at little to no cost, but it also decreases the carbon footprint of your home drastically.

Using recycled building materials decreases the amount of building waste. A study shows that in 2003, the amount of construction waste in England was 91 million tonnes (about 182 cargo ships worth) – that’s an incredible amount of waste that can be put to good use.

The fewer carbon emissions released by the production process of your building materials, the better. And since most recycled materials are being reused, there is no processing required.

Final Thoughts

Using recycled building materials to build your home isn’t the most convenient or easiest route to go. However, using recycled and green materials reduces your carbon footprint and reduces construction waste drastically.

It’s exciting to see what new green materials are being discovered every year and how they’re being used in the construction industry. Innovation and creativity are key to using recycled material in your build, adding new challenges that can be fun.