As the popularity of off-grid living and outdoor adventures increase, so does the need for reliable power sources.

Lithium batteries have emerged as a popular choice for their high energy density and long lifespan. However, it can be challenging to charge them when you’re away from traditional power sources. Fortunately, a very clever way to circumvent this issue exists that involves an alternator.

The alternator is an essential part of your car. While driving, it converts mechanical energy into electrical energy. This energy charges the starter battery and powers your car’s electrical system.

In this article, we discuss everything you need to know to effectively charge your lithium battery with an alternator. Additionally, we walk you through the process step-by-step and highlight the dangers involved with this practice.

Table of Contents

Can you charge a lithium battery with an alternator?

Yes, you can charge your lithium battery with an alternator. There are three ways you can connect an alternator to your lithium battery:

- Parallel connection.

- DC-DC charger.

- External voltage regulator.

Regardless of the method you choose, it’s important that you exercise caution.

Unlike traditional lead-acid batteries, lithium batteries require a specific charging profile, so you must use a battery charger that matches up well with lithium batteries.

Additionally, you must ensure that the charging voltage and current are within the battery manufacturer’s recommended range and monitor the battery’s temperature during charging.

Note to our readers: Even though any AC electrical generator can be technically called an alternator, we’re using the term alternator to refer to automotive or marine alternators.

What is an alternator?

Source: sunautoservice.com

A vehicle’s alternator is an essential component of its electrical system, responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems.

The alternator converts mechanical energy from the engine’s rotating crankshaft into electrical energy. It does this through a rotor and stator system, where the rotor spins inside the stator, creating a magnetic field that induces an electrical current in the stator windings.

A voltage regulator regulates the electrical power produced by the alternator to ensure that the battery and electrical system do not succumb to excessive voltage or current.

Essentially, the alternator is responsible for keeping the battery charged and providing electrical power to your vehicle’s electrical system while the engine runs.

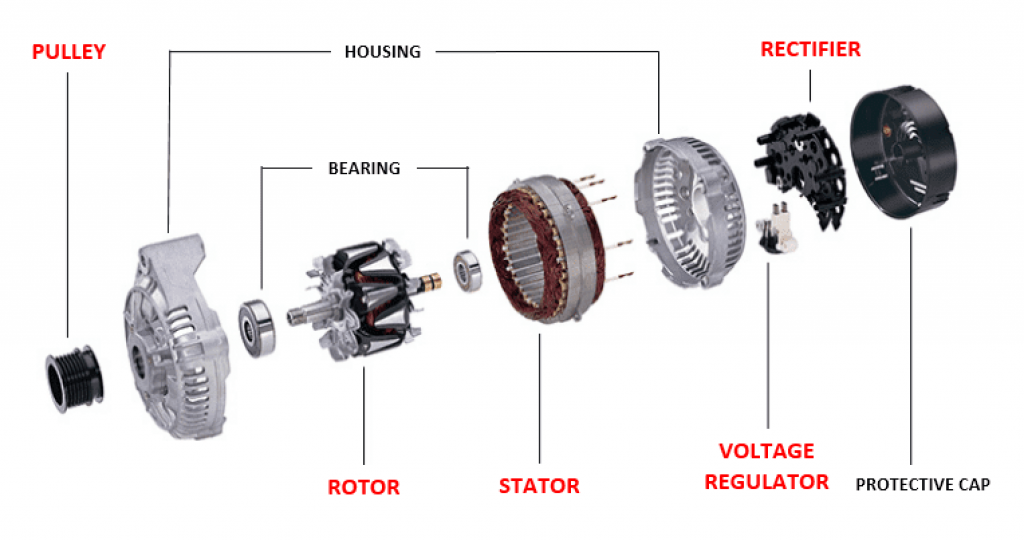

An alternator’s components

Source: Autocar-inspection.blogspot.com

An alternator includes the following components:

- Housing: Usually made of aluminum, given its lightweight and paramagnetic properties.

- Rotor: A rotating magnetic element made of a wire coil enveloped around a magnet (two iron “claws”).

- Stator: A stationary part that houses three sets of copper wire coil windings. It’s fixed to the shell of the alternator.

- Voltage regulator: Limits the alternator’s voltage, ensuring it stays in the appropriate range (12V to 14V).

- Rectifier: Converts the alternating current (AC) to direct current (DC).

- Pulley: Connects the engine to the rotor shaft through a drive belt. Its function is to rotate the rotor as the engine runs.

- Bearings: Support the rotor shaft, allowing the rotor to rotate freely.

How does an alternator work?

An alternator works according to Faraday’s Law of Induction. In short, this law states that any change in the magnetic field of a coil of wire will induce a voltage in the coil.

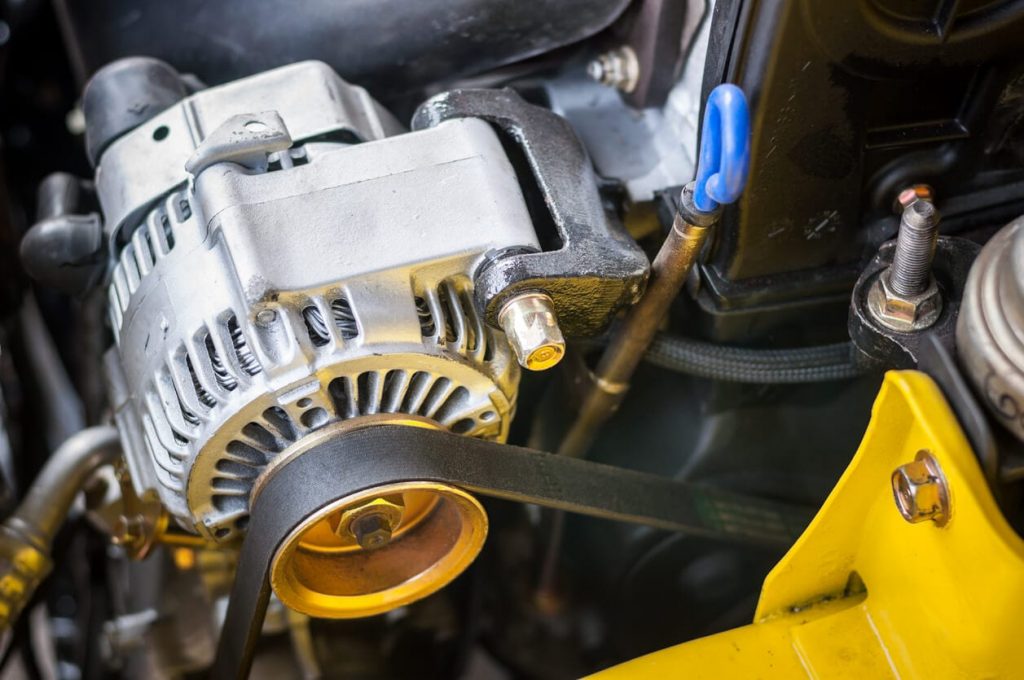

As previously mentioned, the alternator is connected to the engine through a drive belt. This belt connects the alternator’s pulley to the engine’s crankshaft.

Source: club.autodoc.co.uk

Therefore, when you turn on your car’s engine, its crankshaft begins rotating. Thus, the alternator’s pulley (connected to the rotor shaft) also rotates.

The starter battery initially provides a small amount of electricity to the rotor’s coil. This electricity passing through the coil generates an electromagnetic field.

Two iron “claws” (the electromagnet) enhance this magnetic field. One is the magnet’s south pole, and the other is the north pole.

As the engine turns the shaft (rotating the magnet), the changing magnetic field induces a current flow in a set of coils (the stator), as predicted by Faraday’s Law.

Because the magnetic field on the rotor alternates polarity (north/south), the direction of the flow of current induced in the coil also alternates many times per second. Thus, an alternator generates alternating current (AC), hence the name “alternator.”

Since the car battery and its electrical devices need direct current (DC), every alternator has a rectifier. The rectifier converts the alternating current (AC) generated by the alternator into direct current (DC).

Here’s a great video explaining how car alternators work if you’re more of a visual person:

How do you charge a lithium battery with an alternator?

Now let’s get to the “hands-on” part of adapting your alternator to charge your lithium battery bank.

With a few tweaks here and there, you can use the same alternator that charges the car battery and powers the car’s electrical system to charge your off-grid lithium battery bank (your “house” batteries).

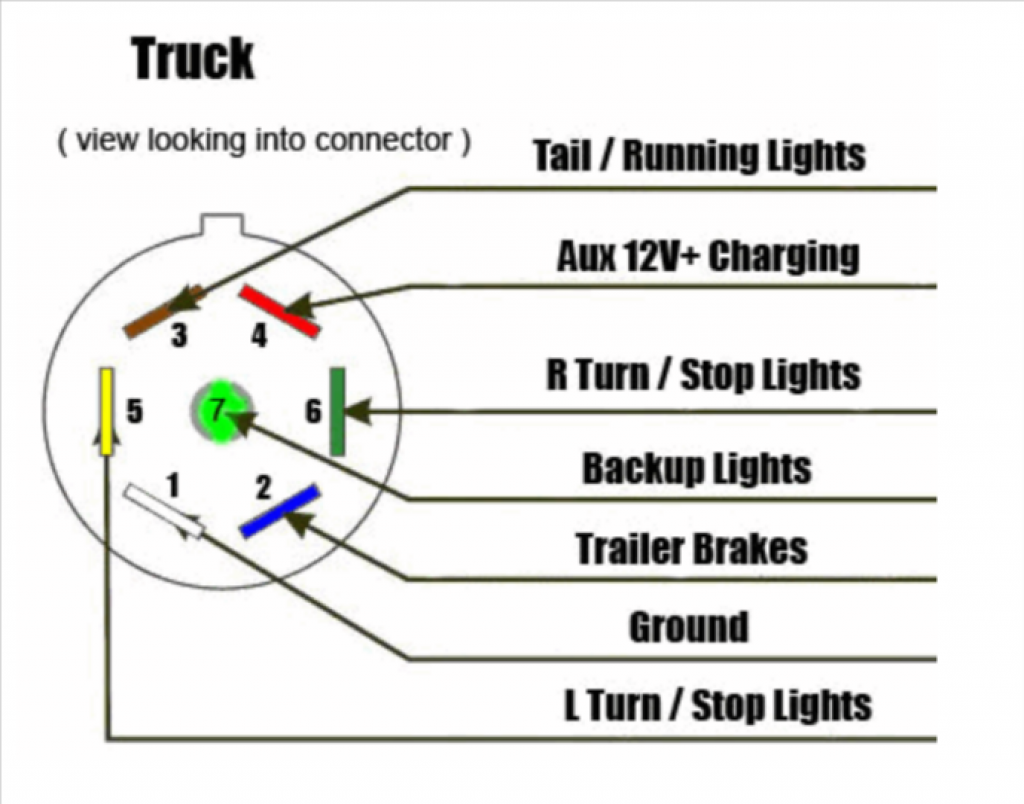

Some modern RVs are already set up to do this. If you connect it with a 7-way adaptor, it should be able to provide a current to charge your auxiliary 12V batteries (house batteries) while you drive.

Here’s a detailed diagram of a 7-way adaptor:

Source: ajtnt.com

However, because this energy also powers all the RVs devices (like shown in the image above), the current that reaches the house batteries is relatively low (usually less than 5A). Therefore, this is not the most efficient way to charge your lithium battery with an alternator.

To efficiently charge your lithium battery with an alternator, you must make certain changes to your vehicle’s electrical system.

Several possible configurations exist for charging a lithium battery with an alternator. Some use battery isolators, and some use a split-charge relay.

In this article, we discuss three configurations.

Three different ways to connect your alternator to your lithium battery

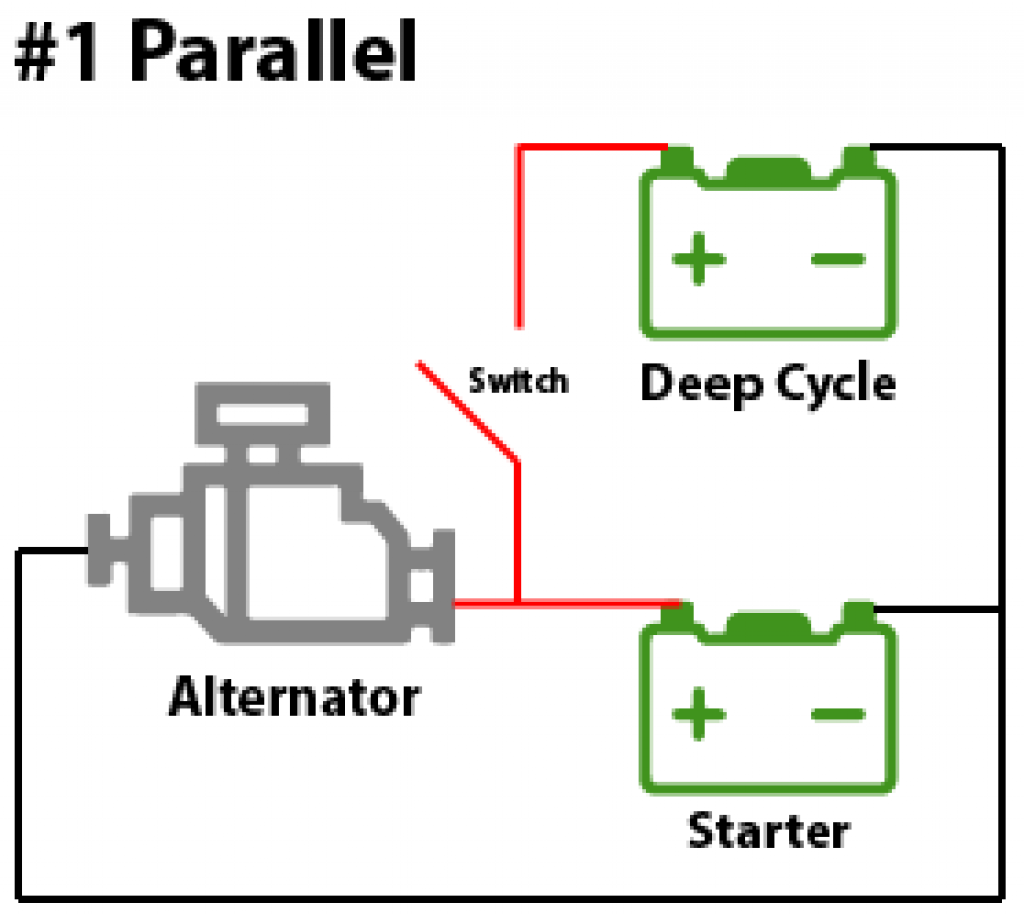

1. Parallel connection

In this setup, you connect the alternator straight to the starter battery and then place the lithium battery in parallel with the starter battery, like so:

This setup is easy to install, and you don’t need any special equipment.

However, the major downside is that this configuration will negatively impact your battery’s life and your alternator. Additionally, the charging speed won’t be optimal because the voltage provided by the alternator will be used to charge both batteries (starter battery and solar battery).

Moreover, it’ll charge both batteries with the same voltage (single-stage charging) — this is far from ideal, especially when charging different battery chemistries.

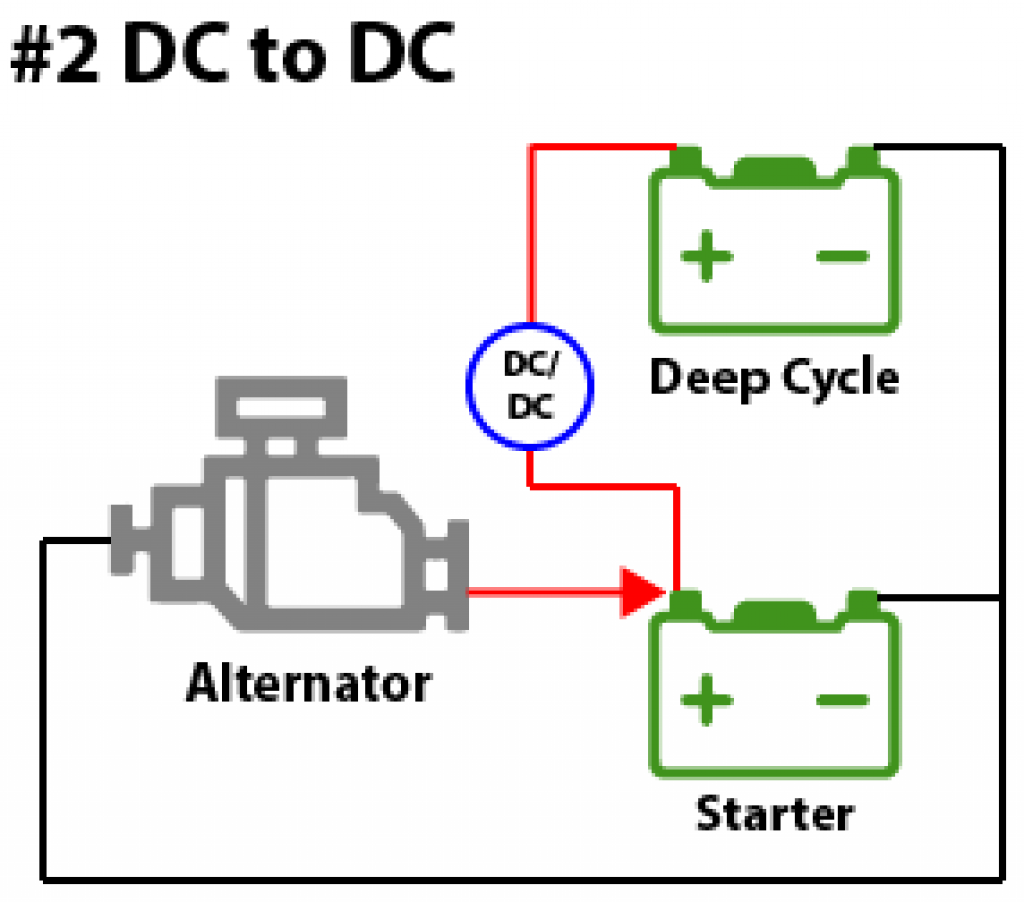

2. Using a DC-DC charger

You can connect your alternator to your starter battery and then link your starter battery to your lithium battery via a DC-to-DC charger. A simple wiring scheme for this configuration is shown below:

This setup beats the first one. Why? Because the DC-DC limits the amount of current going into your lithium battery. This way, it doesn’t damage your alternator by constantly drawing a large amount of current — it only draws a safe amount of amperage.

You can also adjust the DC-DC charger to provide the correct lithium battery charging algorithm.

The problem with this setup is that it draws current from the starter battery, which can considerably slow the charging process of the lithium battery.

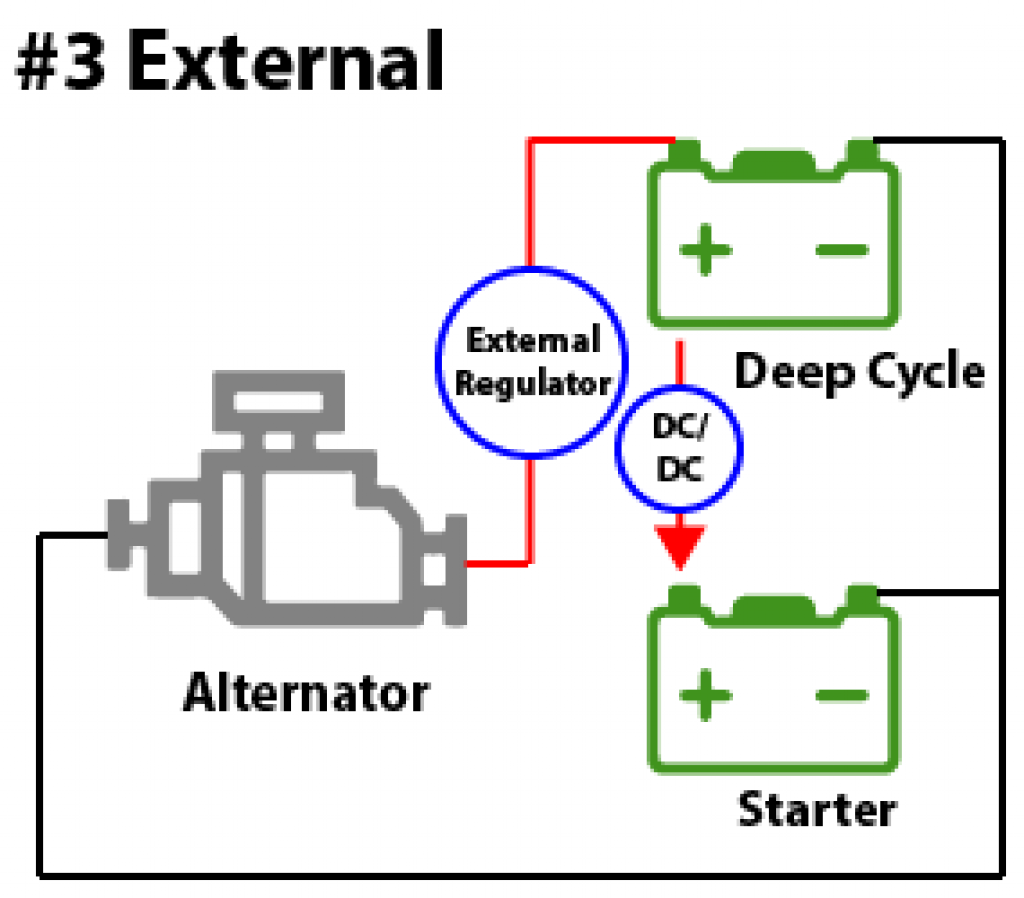

3. Using an external voltage regulator

With this configuration, you use an external voltage regulator to connect the alternator to the lithium battery. Then, you use a DC-to-DC charger to connect the lithium battery to the starter battery, as shown in the image below:

This configuration offers many advantages:

- It optimizes the alternator, allowing fast charging for your lithium battery bank and starter battery.

- It provides the correct charging profile, as required by the lithium batteries.

- The DC-DC charger also ensures the starter battery is charged correctly with the proper charging settings.

Drawbacks

However, significant drawbacks of this configuration include high additional costs (especially with the external regulator), a relatively large system (with two extra devices), and increased installation complexity.

Therefore, considering efficiency and costs, the most recommended configuration would be number 2 — connecting your alternator to your starter battery and then linking your starter battery to your lithium battery via a DC-DC charger.

In fact, if you search for tutorial videos online on how to charge a lithium battery with an alternator, you’ll find that configuration number 2 is the most widely used.

Using a DC-DC charger to charge a lithium battery with an alternator

Think of a DC-DC charger as an intelligent battery charger that uses DC power — from your alternator (using an external voltage regulator) or another battery, for instance — as a source to charge your house/solar batteries.

In addition, you can set it up to provide the correct charging profile for lithium batteries and AGM & Gel, etc. Its primary purpose is to regulate/limit the current going into the lithium battery. This prevents damage to both the DC power source and the lithium battery.

Without a DC-DC charger, charging lithium batteries using another DC power source would negatively impact the service life of both devices.

It’s time to get your hands dirty

Apart from essential tools (like pliers etc.), here’s what you’ll need:

- DC-DC charger (with a rated amperage compatible with your alternator’s size).

- Connecting wires (with the correct gauge/length).

- Fuses.

- Lug terminals (for the connecting wires).

- Switch (optional – only if you want to cut off the supply to the DC-DC charger manually).

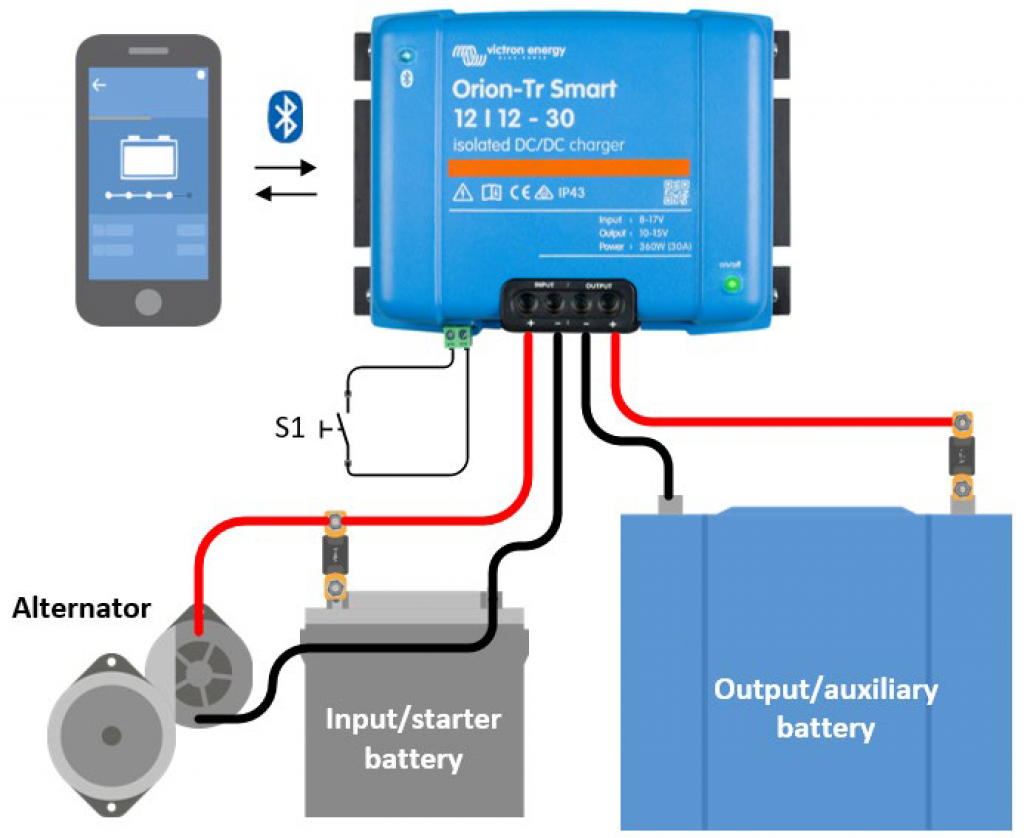

Once you have all the required materials — and assuming the alternator is already correctly connected to the starter battery — you’ll need to follow these steps:

- Connect the starter battery to the DC to the DC charger’s input.

- Connect the lithium battery (in this case, called “house” or “auxiliary” battery) to the DC-DC charger’s output.

- Make sure to connect the “ignition wire” to your vehicle’s electrical system so that the DC to DC only starts charging the lithium battery when the engine is running (so you don’t accidentally drain your starter battery).

Pretty straightforward, right? Here’s a simplified scheme for this system, as provided by Victron Energy:

After connecting all the parts of this system correctly, you’ll be ready to charge your lithium battery with an alternator successfully.

It’s important to note that this is just one of the many possible configurations for this system.

You can adjust this setup according to your needs and preferences. Whatever the case, take precautionary measures to avoid damaging your alternator and/or lithium battery bank.

How much current does an alternator produce?

According to an experimental study on the effect of alternator speed on the car charging system, the power that an alternator can produce is determined by the alternator’s rating, and it can range from 40 Amps up to 120 Amps.

DC-DC chargers are also rated in terms of how much charging current they can provide. The most common commercially available DC-DC chargers provide 20 Amps, 40 Amps, or 60 Amps.

Source: renogy.com

The amount of charging current going into your battery will determine its charging time. The higher the current, the faster it charges. However, each battery has a limit to the charging current.

Going over this limit may damage the battery or not charge at all if the battery management system (BMS) kicks in to protect the battery from this overcurrent.

Therefore, it’s important to consider the right current for your battery to choose the appropriate DC-DC charger.

What are the dangers of charging with an alternator?

There are a few challenges related to charging lithium batteries with an alternator. If you overlook the necessary precautions, this charging setup can prove inefficient and dangerous in extreme cases.

Here are a few problems that can arise when opting for this charging system and how to avoid such issues:

Overheating your alternator

Because lithium batteries present a low internal resistance when their state of charge is low (around 40% to 50%), they can draw a large amount of current from the alternator.

This high amperage output can be too much for the alternator to handle. In such cases, the alternator will overwork, generating considerable internal heat, which won’t be able to dissipate properly.

Therefore, it’s crucial to use a DC-to-DC charger to limit the amount of current drawn from the alternator.

Furthermore, the amperage from your DC to DC charger must match the maximum amperage output of your alternator.

This way, it won’t draw more current than the alternator can safely provide, preventing premature damage to your alternator.

Here’s a video from Victron Energy showing what can happen to your alternator:

Overcharging the lithium battery

Although most lithium batteries have built-in battery management systems, you should always be careful not to overcharge them.

Because the amount of current generated by the alternator depends on the rotation speed of its rotor (thus, the engine speed), it won’t consistently deliver the same amperage. The faster it spins, the higher the amperage output.

Therefore, using a DC-to-DC charger protects the battery from an unsafe high charging current.

Using improper wires: thickness/gauge and length

Using the correct wire (thickness/gauge and length) is crucial to prevent it from overheating, catching fire, or “exploding.”

Why? A wire offering too much resistance to the flow of electrons will generate a lot of heat, possibly resulting in a completely damaged, burned wire.

“But how is the wire’s resistance affected by its thickness and length?“

- Resistance and wire length are proportional: The resistance in a wire increases as the length of a wire increases.

- Resistance and wire thickness are inversely proportional: The wire’s resistance increases as the wire’s thickness decreases.

Think of it this way: when electrons flow through a wire, they collide with ions along the way. The longer the wire, the more collisions, and the more collisions, the greater the resistance.

Conversely, a thin wire has fewer electrons to carry the current, whereas a thick wire has more electrons to move through it. This way, a thicker wire provides a lower resistance than a thinner wire.

“Why is this important?“

If you use a wire too thin for the amount of current delivered by the alternator to the battery, you’ll risk overheating the wires. The increased resistance to the system can also, over time, negatively impact your alternator and/or battery.

Similarly, if you use a wire too long (if the lithium battery bank is located relatively far from the alternator), the same thing can happen — there will be too much resistance, and the system won’t be effective.

To avoid these issues, make sure to choose the correct wire to match the amperage of your charging system. Also, consider the distance between the alternator to the lithium battery.

Draining your starter battery

The alternator only generates power when the engine is running.

Therefore, when you connect the alternator to the starter battery and the starter battery to the lithium battery (via a DC-DC charger), you must ensure that this system only works when the engine is running.

Otherwise, you risk draining your starter battery by charging your lithium battery (a terrible idea) when the engine isn’t running, which means the alternator isn’t charging the starter battery.

DC to DC chargers come with an ignition wire input to avoid this problem. This way, the DC-DC charger only starts charging the lithium battery when the engine is running.

This way, you’re not running the risk of accidentally draining your starter battery.

Final thoughts

So there you have it! You know that you can customize your vehicle’s charging system to charge your lithium battery with an alternator.

This works because the alternator converts mechanical energy from the engine into electrical energy (when the engine is running). This energy is then used to charge the starter battery.

However, with a few adjustments, you can also use this electrical system to charge your lithium battery bank while driving your vehicle.

This is a great way to pump some extra juice into your lithium battery during a long drive or when your solar panels can’t produce enough power to charge your lithium batteries (on rainy/cloudy days).

Using a DC-DC charger for this charging system is critical, being perfect for dual battery systems in vehicles and boats.

Renogy, Victron Energy, Sterling, and Redarc are a few examples of brands that offer high-quality DC-DC chargers.

Even though using an alternator is an effective and cheap way to charge a lithium battery, the system should be carefully planned and installed. This way, you’ll avoid any possible problems with this charging setup, like prematurely damaging your alternator or lithium battery.